The cleanroom ceiling joist system is designed according to the characteristics of the cleanroom, with simple processing, convenient assembly, and disassembly, and convenient daily maintenance after the cleanroom is completed. The modular design of the ceiling joist system has a great figurability, which can be factory-produced and can be cut on-site, greatly reducing the pollution of processing and construction, and has High system strength, which can be walked on it, especially suitable for high-clean areas, such as electronics, semiconductors, medicine industry.

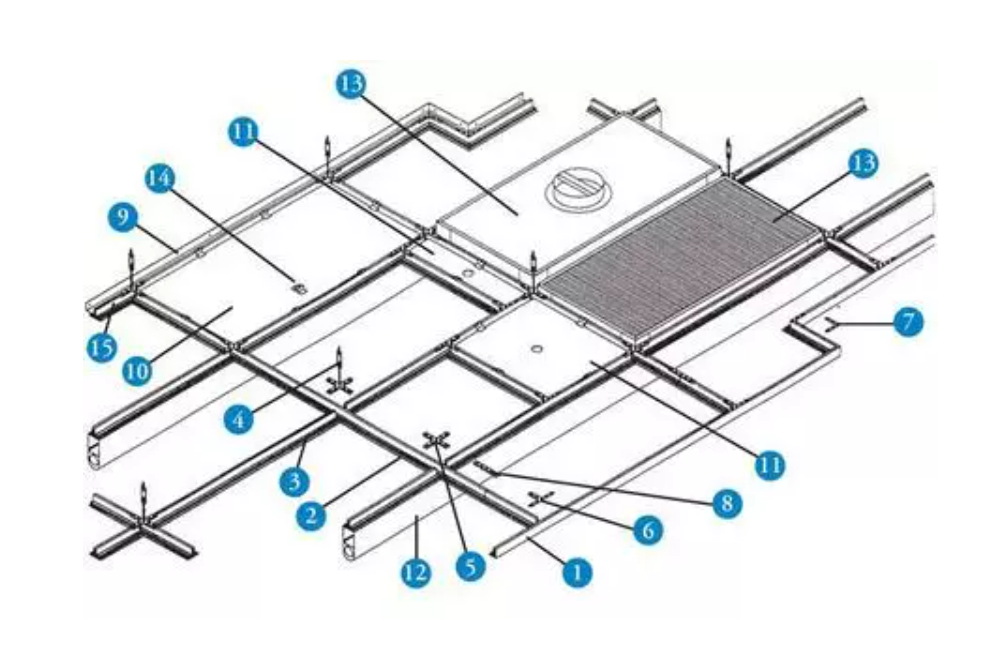

Composition of ceiling joist system

1. T-bar:

1) T-shaped structure, dry ceiling, anodized aluminum material, surface electrophoresis treatment

2) Sprinkler heads, smoke detectors, and wires for lighting lamps can be installed at the T-bar cross joints.

3) Cleanroom teardrop lighting can be installed under the T-bar

2. Joint:

1) The connectors include cross joints, T-shaped joints, corner joints, and zinc alloy materials. The whole system is connected by screw threads to form a whole.

2) Galvanized full wire boom with an adjuster to adjust the height of the ceiling, connected by clips and nuts.

3) The screws and nuts are all galvanized materials

3. System expandability: It is convenient to install a high-efficiency filter, FFU, etc.

Joint of the cleanroom ceiling joist (schematic diagram of cleanroom ceiling joist)

1. Check the baseline

2. Check the datum elevation line

3. Boom prefabrication

4. Boom installation

5. Ceiling joist prefabrication

6. Ceiling joist installation

7. Level adjustment of the ceiling joist

8. Positioning of the ceiling joist

Post time: Mar-29-2022