Cleanroom construction is an essential part of many industries, including pharmaceuticals, biotechnology, and microelectronics. A critical aspect of cleanroom design is the selection of materials that meet the strict cleanliness and sustainability requirements of these facilities.

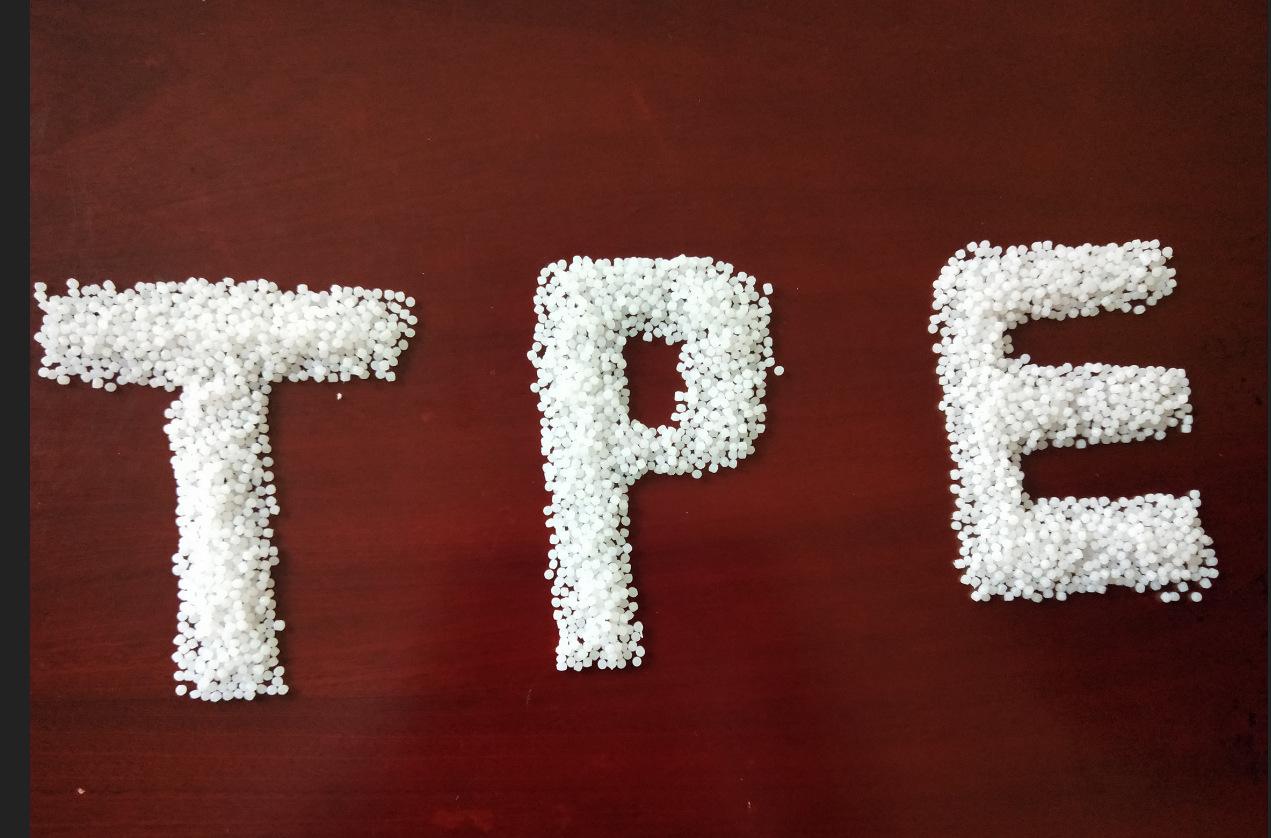

A new innovative material, developed by a leading cleanroom materials company, offers significant advantages over traditional materials in terms of both performance and sustainability. This material is a thermoplastic elastomer (TPE) that is specially formulated for use in cleanroom environments.

Compared to traditional materials such as polyvinyl chloride (PVC), the TPE material offers superior durability, flexibility, and resistance to wear and tear. It is also resistant to chemicals, making it ideal for use in cleanroom applications where harsh chemicals may be present.

Furthermore, the TPE material is more sustainable than PVC and other traditional materials. It is free of phthalates, halogens, and other harmful substances, making it a safer and more environmentally friendly choice. It is also recyclable, reducing waste and promoting sustainable practices.

The TPE material has been successfully used in a range of cleanroom applications, including walls, floors, and ceilings. It is easy to install, reducing construction time and costs, and requires minimal maintenance.

The use of innovative materials such as TPE demonstrates the commitment of the cleanroom industry to continuously improving the performance and sustainability of cleanroom facilities. As the demand for cleanroom applications continues to grow, the development and adoption of such materials will become increasingly important to ensure that cleanroom facilities meet the highest standards of performance and sustainability.

In conclusion, the use of innovative materials such as TPE offers significant advantages in cleanroom construction, including improved performance, sustainability, and ease of installation and maintenance. As the cleanroom industry continues to evolve, the adoption of such materials will be essential to meet the demands of the market and ensure the reliability and effectiveness of cleanroom facilities.

Post time: Apr-20-2023